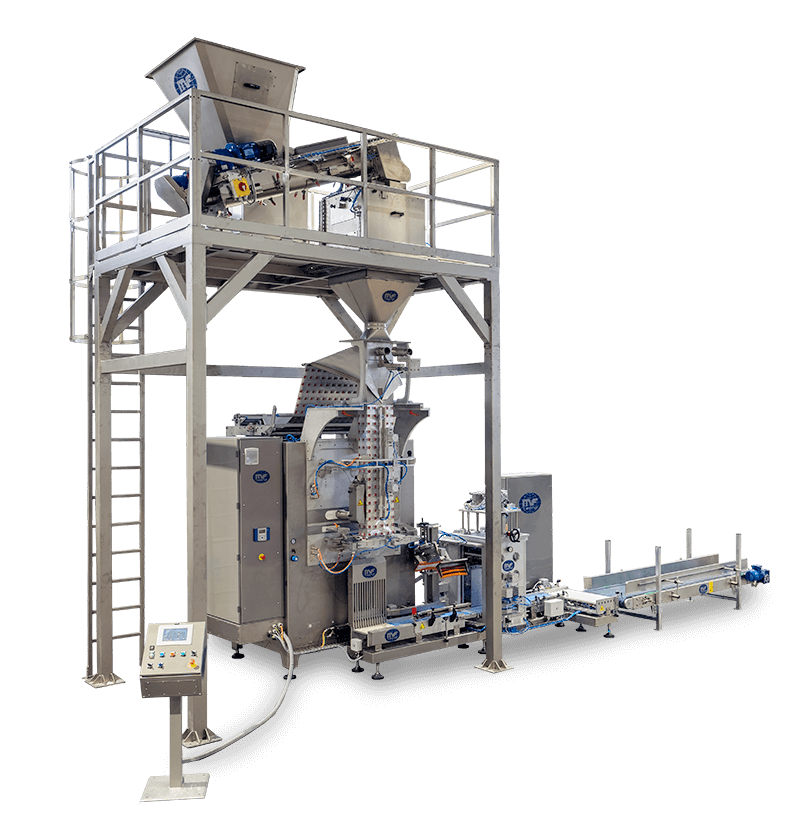

MF TECNO offers many feeders for electronic weighing machines: with vibrating channel (single or multiple), belt, horizontal screw, gravity, turbine. Each have different features depending on the type of product to be packaged. They can be installed over any automatic or semi-automatic packaging machine.

Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more