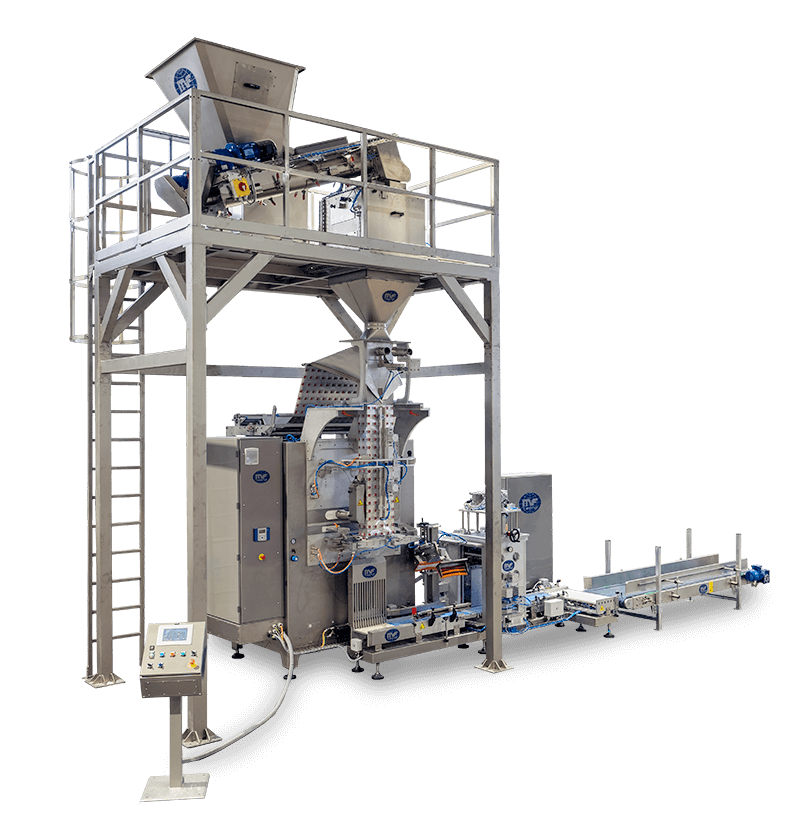

The necessity to adapt to the various production contests and the requests of each individual customer, has meant that it is essential for MF TECNO to have a wide range of the important accessories. The accessories improve the preliminary bagging process phase, the intermediate bag closing phase and the last phase, where the bag is inspected and subjected to various checks to guarantee the suitability of the final result.

Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more