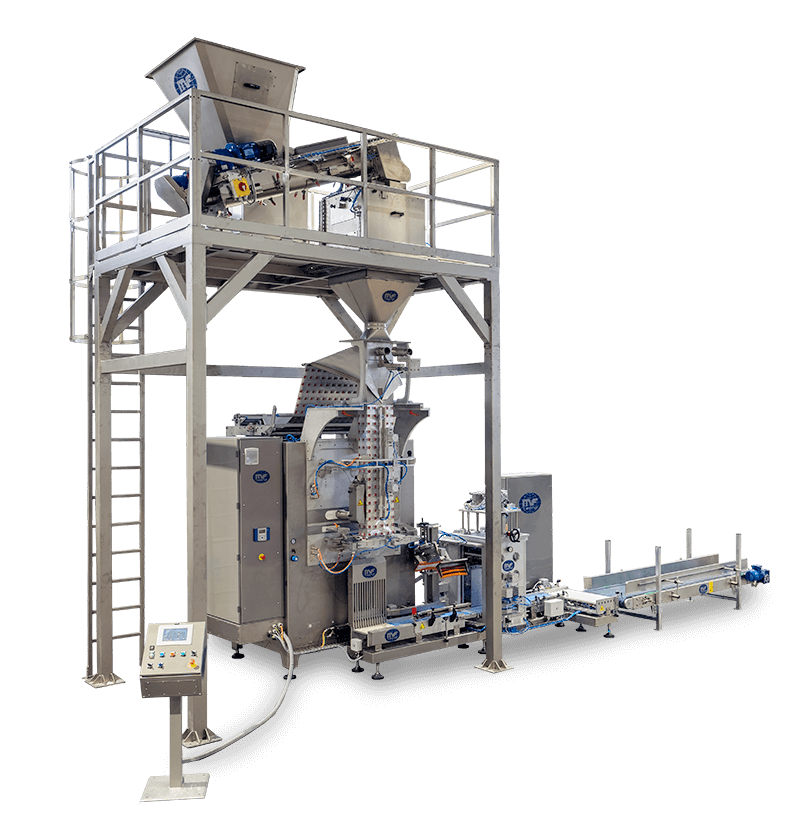

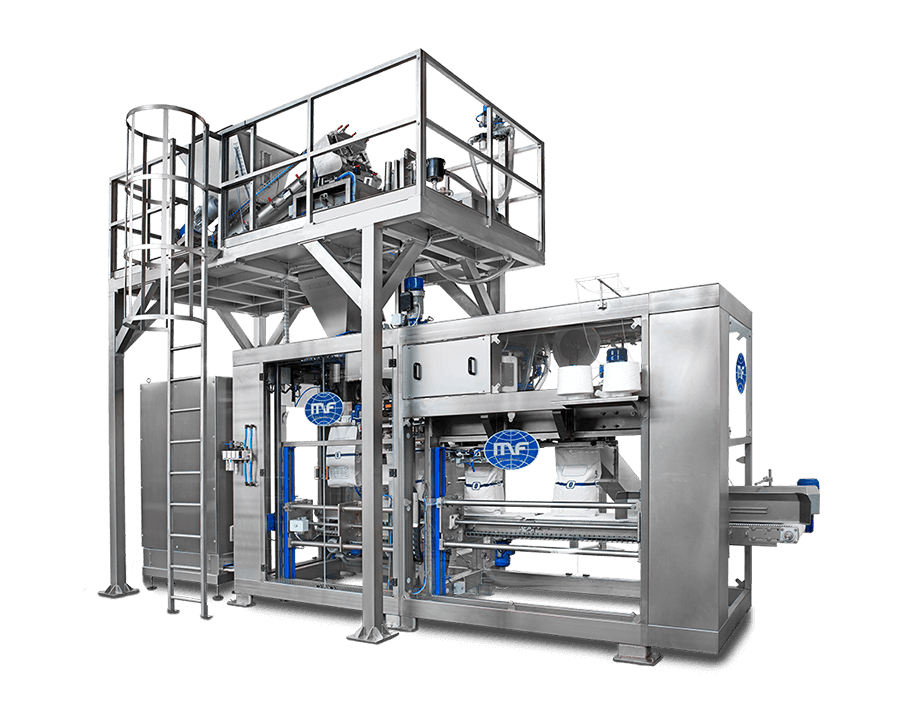

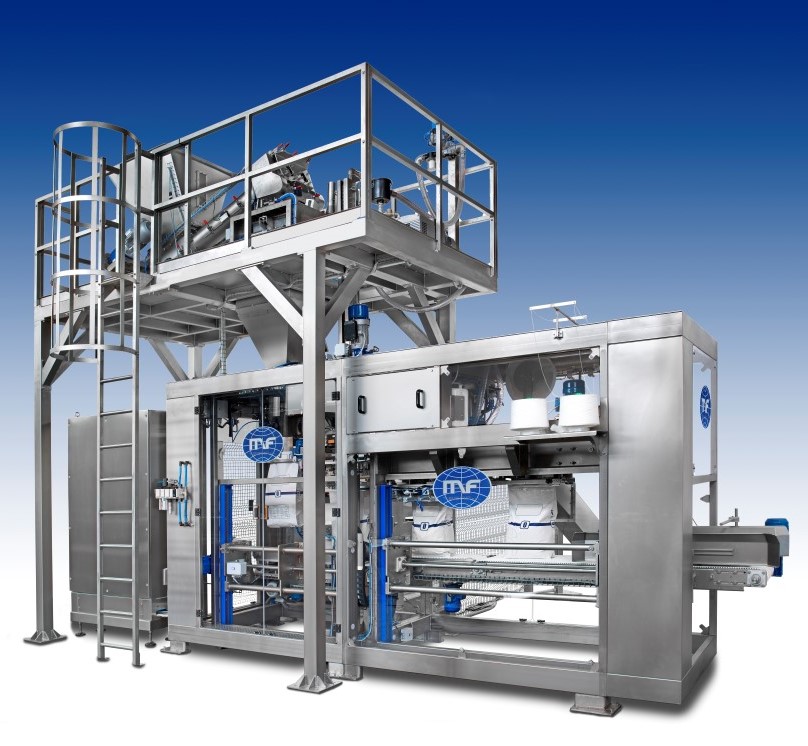

Automatic bagging machine for gusseted and non-gusseted open-mouth bags. Ideal for packaging flours in a wide range of formats.

The IABA 600 F bagging machine is designed to fill and close pre-formed bags easily and reliably. Developed for medium and high production. It is the perfect solution for packaging flours and similar products.

Thanks to the presence of a double vibration/compacting station, which allows excess air to be eliminated, the IABA 600 F can reach high production and quality levels.

Its single-piece structure and "step-by-step" handling of the products, elements typical of the IABA series, allow any type of bag, with or without gusset, to be treated with maximum precision and efficiency. Transfer speed is guaranteed by servo-assisted movement with brushless motors.

Request information

Request information  Download pdf

Download pdf flat, gusset, no gusset, pinch-top

aluminised paper, laminated raffia, paper, PE, PE coated paper, PP

There are many reasons to choose our products

Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more